Aseptic processing is the process by which a product (typically a liquid food or pharmaceutical) is rendered sterile, then filled into a sterile container in a way that maintains sterility in the finished, sealed package.

Aseptic bag filling

How does Engi-O achieve this?

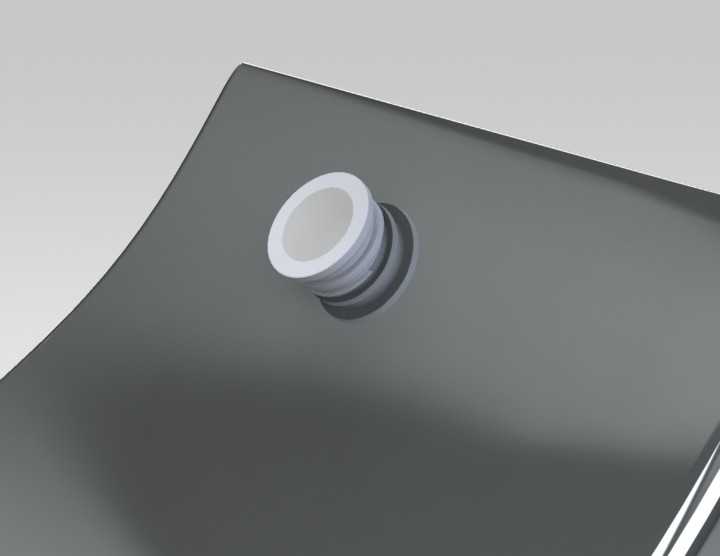

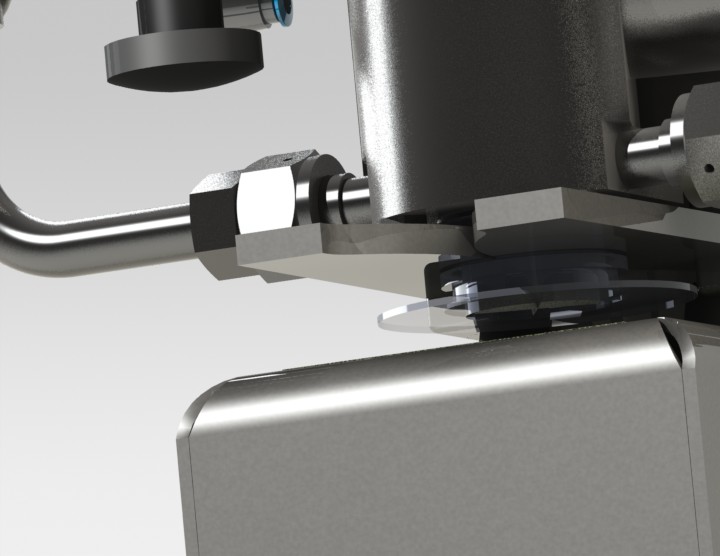

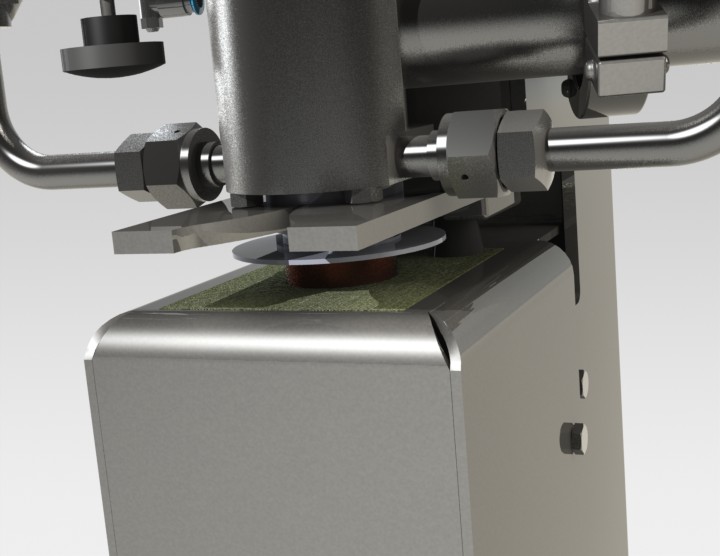

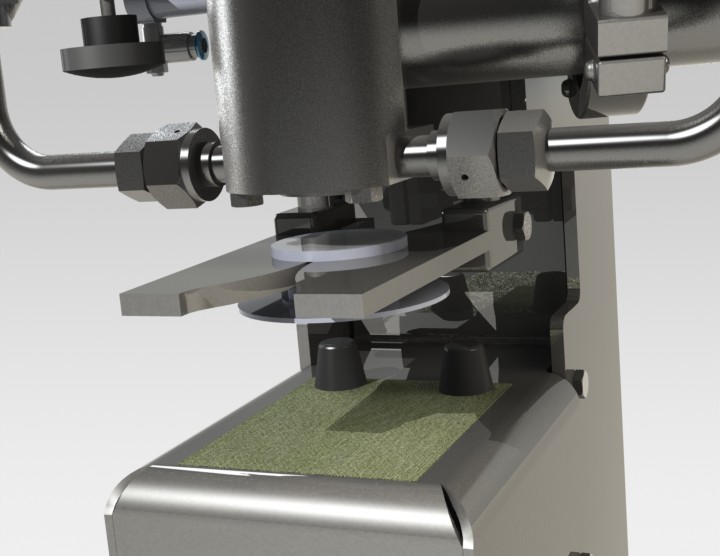

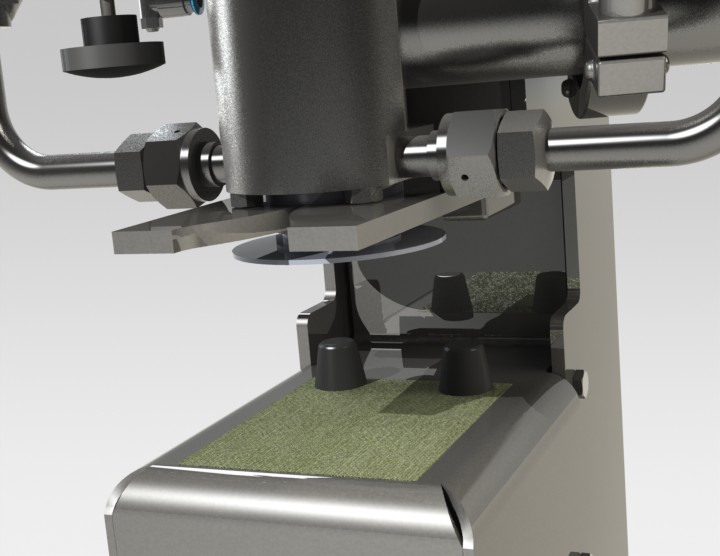

The safest technique available uses a special filling gland with a membrane on its surface. The assembly is then welded into the bag. The bag is then packed in a shipping box where it is sent to a Gamma Irradiation plant. The bags whilst empty in the box on a pallet are sent around the radioactive source sterilising the bag.

This video explains how to fill the bag under sterile conditions.

Aseptic Info Video

Click here to find out how to make the Aseptic Product.

The small chamber separating the gland membrane to the product is steam flushed to get rid of the air and then sterilised. This heat process can be adjusted to suit the F0 value applied to the product. Remember that the membrane has very little bioberden.

This Aseptic method has been proven over years of industry production for liquids such as Milk, Coconut Milk, Tomato Pastes, Juice concentrates, low acid or high acid.

Thanks to Entapak Asept-E-Seal for their gland used in this demonstration. For more information, have a look at their website.

The other glands and plugs shown can also be filled Aseptically using Hydrogen Peroxide to sterilise. This range of fillers is in the design phase at present.